Laser Slat Cleaner Price

Save time and money using this method.

Laser slat cleaner price. Dual cutters lift slag from both sides of the slats. To the product. While copper slats are more expensive than steel they pay for themselves with reduced time and cost for replacement and cleaning. Slat cleaning tool for co2 and fiber laser cutting machines cleans a standard laser table in approximately 15 min.

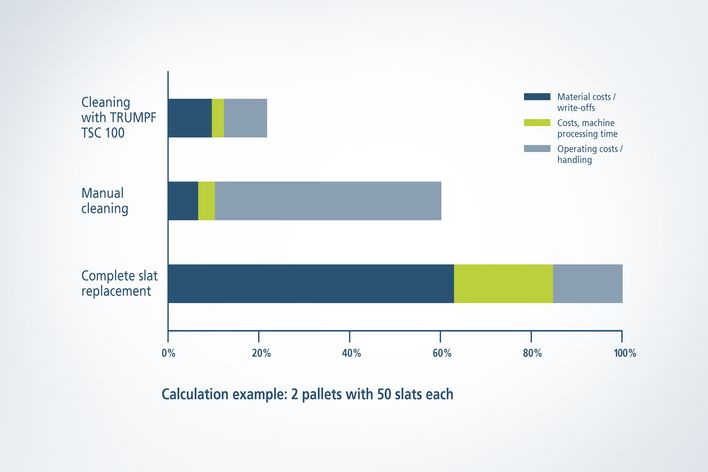

Without regular slat cleaning however the molten metal has nowhere to fall possibly causing a part to be welded to the grating or simply causing the. It achieves savings of around 40 compared to manual cleaning which involves a lot of effort and time. Professional manufacturer of laser slat cleaner for laser cutting machine. Slatpro is not affiliated with any of the laser machine manufacturers given on this page.

With the ability to clean slats multiple times it is possible to save up to 75 of costs compared with regular slat replacement. The trutool tsc 100 is a worthwhile purchase. Extend the life of your support slats on your 2d laser machine by cleaning them with the trutool tsc100 slat cleaner. C up removes both slags oxidised residual easily avoiding any kinds of contamination on stainless steel.

For use on most manufactures laser machines bystronic trumpf amada mitsubishi mazak and more weight. Make laser slats cleaning easy. Trutool tsc 100 the slat cleaner thoroughly removes the slag on the slats of the laser cutting machine. Designed for one man operation this he.

Laser slag removal tool specialist. C up makes slats live longer and improve the quality of cut sheet metal. New tool for cleaning slats of laser cutting machines. Clean tough laser slag on laser slats table thoroughly with one ideal laser slat cleaner.

Corporate names and trademarks stated in this website are the property of the respective companies. Figure 1 these grates used to have peaks and valleys at the top so that they could solidly support the sheet metal being laser cut while at the same time provide room for the molten metal to drop away from the sheet and adhere to the slat. How to clean your slag on your laser slats like a pro. Quality of cut parts improves as there is reduced slag build up that causes the laser to bounce back and mar the bottom surface of the cut material.

Thanks to two spinning wheels c up is able to move and maintain intact slats characteristics over time. This video demonstrates how you do it like the pros. Keep laser slats clean always. The laser slat cleaner automatically adapts to different slag thicknesses of up to 1 in.

Check out our roi calculator to see if copper is a good fit for you.